News & Events in Belarus

Lukashenko's role in turnaround of Mogilevliftmash, now best elevator producer in post-Soviet space

Aleksandr Lukashenko visits Mogilevliftmash, July 2023

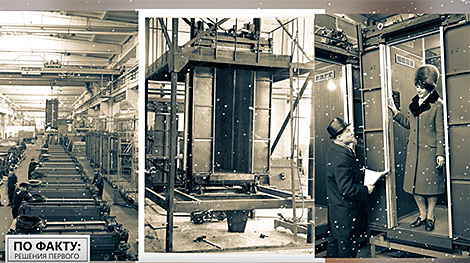

The Soviet era was a period of heroic deeds. In the post-war years, people spared no effort to revive and rebuild cities and republics. For the BSSR, this time was marked by the accelerated development of all kinds of industries. The factories built then would later become the signature brands of Belarus. These are, for example, BelAZ rock haulers, Belarus tractors and Minsk refrigerators. By the way, we ran dedicated episodes about these enterprises. Be sure to check them out. Highly recommended! Most probably you know such brands as the Aist bicycle and the Luch watch. Microelectronics was also growing leaps and bounds. At the end of the 1960s, another enterprise was built on the outskirts of Mogilev, which in a few years became another signature brand of Belarus. This is Mogilev Elevator Plant, the focus of our today's episode. We will tell you why builders from all over the USSR flocked to the Belarusian city on the Dnieper River and why every second worker of Mogilevliftmash was awarded the Shock Worker of Communist Labor title. Why the industrial flagship had to switch to the production of trailers and lifting winches in the 1990s and how the Belarusian president saved the enterprise at the turn of the 2000s.

How did Belarus come to produce elevators

Mogilevliftmash was not the pioneer of elevator manufacturing in the BSSR. Initially, elevators were made by Strommashina, another Mogilev plant. It rolled out its first elevators in 1964. But the growing economy required more and more elevators, and the non-specialist manufacturer simply could not cope with the demand. In 1966, the USSR Council of Ministers okayed the project to build Mogilev Elevator Plant. The company was supposed to provide elevators for the main construction projects in the Soviet Union.

Brigades from all over the USSR took part in the construction of the new plant. The equipment was installed in temporary production areas even before the workshops were completed. The machines were brought from Ukraine, Georgia, Kazakhstan, and Lithuania. The elevator plant construction project was under special control of the government: from the district administration to the Supreme Soviet of the USSR. By the end of 1968, the plant rolled out its first product, a speed limiter, and a little later it started producing other parts and units.

In the 1970s, Mogilevliftmash started making passenger elevators with a carrying capacity of 350kg and a speed of more than 0.5m per second. The first passenger elevator was installed in the building of the House of Soviets in Mogilev. Since then the plant celebrates its hundred-thousandth milestones by installing elevators only at facilities in Mogilev.

A couple of years later, orders for Belarusian elevators began to pour in from Moscow, Volgograd, Leningrad, Rostov and other cities. In the 1980s, they were supplied to hundreds of cities across the USSR and also to Hungary, Poland, Vietnam, Mongolia, and Pakistan. The plant carried out military orders too. It made elevators for the Baikonur Cosmodrome and elevators for rocket silos. The work of factory workers was appreciated. The Shock Worker of Communist Labor title was awarded to almost every second worker.

The difficult time of the 1990s

But the collapse of the USSR and, as a result, the severance of economic ties and inter-industry cooperation immediately affected the enterprise. Mogilevliftmash began to lose orders and slide into recession. In 1991 the factory produced a record number of elevators of more than 14,000 (still a record). In 1993 the output was below 4,000. In 1996 it was only 1,700. In order to survive, the plant decided to switch to the production of consumer goods. It produced electric cultivators for cultivating land, trailers for passenger cars.

"I came to work at the plant in April 1989 after graduating from Mogilev Polytechnic School. The plant was already struggling. There was little work. Layoffs were all around. Sales markets collapsed. I was offered to switch jobs and move to the consumer goods department. I worked there almost my whole life. It wasn't easy either. The elevator business was no gravy train back then; times were hard and there was no money. Only the consumer goods department was doing pretty well; it assembled machines and agricultural winches. I remember there was no heating. But the director tried very hard and supported us all the time. He said: “Girls, tough it out.” Component parts were cold, my hands were frostbitten. Nevertheless, we kept working, we tried to warm ourselves up. Selling our products was just as challenging,” recalled Svetlana Kholomeyeva, an assembly mechanic with the assembly and painting shop.

Lukashenko's first visit to Mogilevliftmash

The situation began to change only at the end of the 1990s - early 2000s. According to factory workers, the president's visit to the company was a pivotal point. Aleksandr Lukashenko first toured Mogilevliftmash in September 2000. Upon arrival in Mogilev, the head of state first of all talked with its residents, and then headed to the factory. The president focused on raw materials and supplies. He inspected the workshops and studied economic performance. Aleksandr Lukashenko gave a number of instructions to upgrade production and emphasized that the problems outlined by the factory workers should be resolved promptly.

“That was a difficult period. Salaries were around $100 back then. The president first came here in the early 2000s, I think it was in autumn. And about a year later, we started getting equipment. We would come to the workshop to see boxes all over the place. Everything changed dramatically. Not just the workshop, but the entire factory. It was a far cry from what it used to be,” said Aleksandr Patsankov, a laser operator at the metal construction shop.

Aleksandr Lukashenko set an urgent task for the Mogilevliftmash management - to ramp up industrial potential. The president's visit marked the start of a large-scale upgrade effort.

“The president's visit was an inflection point that turned the situation around. The elevator production recovered. The assortment became larger, the equipment was renewed. In other words, the company was back on the right track,” noted Svetlana Kholomeyeva, an assembly mechanic with the assembly and painting shop.

Thanks to the hardworking team and firm position of the country's leadership, the factory managed to overcome the difficulties. By the early 2000s it re-emerged as the industry leader in the post-Soviet space.

“In 2013, I graduated from Mogilev State Polytechnic College and was assigned to the company in line with the mandatory first job placement. I knew that it was one of the best enterprises in Mogilev. We had tours of other enterprises of the city, so we could compare. We wanted to get a job here, because the enterprise was head and shoulders above other companies. When the mandatory work period was over, I decided to stay. At first I worked at the workshop. After I received a higher education, I moved to the chief technologist department to work as an operator of computer-controlled machines, and now I am already writing programs for these machines,” process engineer Kirill Stepanov said.

Why Mogilevliftmash remains state property?

However, new challenges emerged: global economic crises did not spare the export-oriented economy of Belarus. The industrial output shrank, so did revenues. But the government always stands ready to lend a helping hand to those ready to move on.

“The company changed beyond recognition. The only thing that remained the same was its employee-centric culture. People have always come first at the company. We make elevators not only for Belarus, but also for Russia, Kazakhstan, Ukraine; we used to supply our products to the Baltic states. I don't think that a private owner would be just as interested in pushing the company forward. I think that it is good that the company did not go into private hands. It is good that we all have survived,” Svetlana Kholomeyeva said.

The factory workers are right. Effective production needs, first of all, a responsible owner. It is not so important who it will be, the state or a private owner. Yet, during a crisis private businesses will hardly go to extraordinary lengths to retain all the employees. The most important thing for them is profit. By contrast, the government has a completely different priority, which is people.

“There is positive dynamics. I think that after today's conversation the company will gain momentum. We should turn the company around. The situation is not easy, but I see that it is beginning to improve even in Mogilev Oblast. My main concern is to keep people busy, but on one condition: they should want to work. I am ready to help them in every way to find a job. There many jobs and opportunities to create jobs today,” Aleksandr Lukashenko said during his visit to the company in 2016.

There are other reasons why the government does not want the country's industrial flagships to be privatized. These enterprises, as the president emphasizes, are the national wealth. The head of state is against selling off the enterprises that were built by the whole country, by thousands of people. Moreover, foreign investors have solely vested interests in the Belarusian industry.

“We know what privatization is. What do investors do? They let half of the personnel go and make the rest produce what they say. Simply put, you will do blue-collar jobs here while the main competencies, including design bureaus and highly-qualified specialists will be located there, abroad. They lay off half of the staff and keep the rest to assemble something simple. Who will agree to cuts in the production and labor force? Who will want ‘a brain drain'? I will never allow this. I am not even going to discuss such investments with them,” the head of state said in an interview.

How is Mogilevliftmash doing today?

In brief, the order intake is very strong. The company is working on new designs. The Belarusian plant sells more elevators than any other manufacturers in the post-Soviet space. This pertains primarily to the manufacturers from Russia.

“This speaks volumes. It means we make both high-quality and competitive products. Demand for our elevators is strong. This year we have launched a new product - an elevator with a speed of 2.5m per second. This is not our maximum, however. The R&D center has already been tasked with developing and testing an elevator with a speed of up to 4m per second next year. 4m per second is more of a prestige for us. There are elevators with a speed of 8m and even 9m per second. We believe, however, that this segment is not our niche,” deputy chief engineer Yuri Chernogrebel said.

Today, Mogilevliftmash produces about 180 basic elevator models, including passenger and freight elevators and elevators for hospitals and cottages. The plant also makes elevators for physically impaired persons, escalators and travolators, construction elevators and small wood shredders (mulchers), as well as consumer goods.

“Why have I come to Mogilevliftmash (before that to BelAZ, MAZ)? The demand is great now. We need to satisfy the market. Therefore, I have a question: why don't we produce more as the demand is so high? If you lack capacities at Mogilevliftmash, you need to use others', if necessary,” the Belarusian leader said. “It is important that we seize the moment, that we win over the market. If today the demand is, for example, 16,000 units and the plant can produce 14,000, well, we need to find an opportunity to make 2,000 more. Let the plant make the main parts, and Strommashina, for example, do some auxiliary jobs. Thus, we will be able to gain a foothold in the market and get our enterprises operate at their full capacities.”

Talking to the company workers, the head of state said: “The demand for your products is great. Times were not easy for us. You criticized me, even lambasted me on the issues of salaries... We had to look for money elsewhere and do our best to keep these enterprises afloat. Recently we have often heard from our elder brother, as I jokingly call them: ‘You did a good job by preserving this or that enterprise'…”

The plant is running an import-substitution program. The plant is implementing several investment projects. Funds are allocated to launch the hi-tech production of traction electric motors for electric transport and a new series of energy-efficient electric motors. Plans are in place to start the production of high-speed elevators based on gearless drive and modernize the existing production of import-substituting elevators.

Another unusual project of Mogilevliftmash is the production of vertical parking lots. The rotary parking lot, which is also called a carousel parking lot, can accommodate 12 cars, while occupying the area of only two parking spaces. The parking lot is more than 14m high and 7m long. The project is unusual and ambitious, but time will tell how much it is in demand.

Mogilevliftmash is a story about feats. A story about those who sacrificed what they could in order to revive the hometown and the country. A story about those who did not forget the past and never surrendered to the difficulties of the present. A story about those who look into the future today. A story about the decisions that unite these generations.

print version

print version make home page

make home page add to bookmarks

add to bookmarks