Business news

Remember when Lukashenko was treated to Belarusian trout? We went see how it is produced

In September 2023, Belarusian President Aleksandr Lukashenko made a trip to Belynichi District. During the visit, the head of state toured the trout farming section of the Lokhva fishery, where he was briefed on the development of the fish farming industry in Mogilev Oblast and the increased production of valuable fish species. Aleksandr Lukashenko familiarized himself with the fish farming technology and sampled the local products. The fish tasting was a great success. The farm truly put its best foot forward. Salted, smoked, and chilled trout, and, of course, fish soup… The quality was verified by the president. In a special report BelTA will tell and show how all these delicacies are made.

The Belarusian trout, according to the farm managers, is no different in taste from chilled Norwegian fish.

“This is for the governor, and this is for the head of the President Administration. They are slim. They can have it with potatoes," Aleksandr Lukashenko said while tasting the trout fish soup.

“This is good,” Governor of Mogilev Oblast Anatoly Isachenko said giving a thumbs-up to the dish.

How Belarusian trout is farmed

Before Belarusian trout reaches your table, it has a long journey to go. It all starts at the fish farming and industrial complex in Gorki. To be more precise, in the incubation workshop.

We were in luck: when we arrived at the enterprise, they were just preparing to receive a shipment of roe. Once the raw material makes it way here, no one except the personnel is allowed into the premises.

“Each frame holds 12,000-14,000 eggs. We check the condition of the frames and the nets: if anything has come unglued, we re-glue it. We make sure there are no cracks or gaps. We treat our trays to remove limescale. Then we clean all the equipment. We check that the pumps, mechanical seals, and everything else are in working order,” Andrei Astapov, head of the fish farming complex Lokhva Trout Farm, shared the specifics of the work.

The temperature of the eggs is approximately one degree Celsius. The water from the wells is a bit warmer, about nine degrees. To prevent thermal shock, the water temperature in the system must be equalized.

“We freeze ice, add it to trays of water, and break it to rapidly equilibrate the temperature. We then verify the temperature of the eggs. If the eggs are at 1°C, the water must be within a 1.5°C differential; we therefore adjust it to between 2-2.5°C. The eggs are then introduced to this water, and the temperature is gradually increased at a rate of approximately 1°C per hour,” the head explained.

The workshop can be called a maternity hospital. This is where the fry are born. And everything here is arranged in a way to make this process effective.

The fry begin to hatch after two weeks, initially nourished by their yolk sac. Once they swim up to the surface, external feeding begins. They are then systematically relocated: first to a lower tray, and then into tanks.

Raising and feeding Belarusian trout

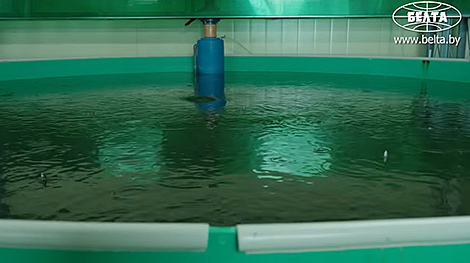

For example, this workshop has eight tanks, each with a volume of 18 cubic meters. When the fish are small, the tanks are initially filled to half their volume. Water is added as the fish grow. Once the tank becomes crowded, the trout are transferred to other facilities.

“Right now, our fish weigh about two grams. At this point, they need to be separated and their density reduced. We try to manage everything in the right time so the fish grow on schedule. Some grow quickly, while others are slower, and they compete for resources. Therefore, it’s better to separate them,” explained Andrei Astapov.

The environment in the tank is carefully controlled, with an oxygen level of 100-110% and a water temperature of 12-14 degrees Celsius. The fry are fed a high-protein diet every three hours, which is more expensive than the feed for adult fish.

Once the fish in these tanks reach 30 grams, they are transported to other branches. The Lokhva trout farm currently operates four such branches.

“We grow 200 tonnes of fish per year in two complexes and 100 tonnes in a third. The total annual volume is approximately 500 tonnes. We export the stocking material. And we sell the marketable fish in Belarus,” noted Yuri Kuksenkov, the Lokhva trout farm director.

The Kosichi branch, for instance, has two modules containing two tanks each. This facility receives stocking material weighing seven grams, after which the fish are distributed to other sections.

“Each tank has a capacity of approximately 1,200 cubic meters, with a stocking capacity of about 350 cubic meters, holding roughly 350 kg of trout in one cubic mater. The feeding process there is fully automated. The water supply comes from artesian wells. There are six wells in total, but only about two are currently in use,” said Vasily Tkachev, chief fish farmer at growing site No. 1 of Lokhva Trout Farm.

This facility operates a Recirculating Aquaculture System (RAS), which involves a daily water exchange of 10-15%. The fish are grown in these tanks until they reach marketable size, which can start from 250 grams. On average, however, they reach about 800 grams. Raising larger trout is not economically viable, the farm explained.

The trout are fed every 45 minutes, which amounts to 14 times a day. The feed is based on fish meal. “We use imported feed, which is balanced. Additionally, the Belarusian National Biotechnology Corporation (BNBC) is currently developing feed specifically for trout species. We are already testing it. It seems promising, but further improvements are needed to fully adapt it for RAS use. There are some nuances to consider, especially since we're working with the same water in a closed system. This requires careful attention,” Vasily Tkachev added.

What can a fish’s mood reveal?

From the station, oxygen is supplied through hoses to additional units in the tanks. When the fish grow larger, the farm needs to additionally oxygenate the water. Particular attention is paid to the behavior and appetite of the trout.

“In order to visually understand the mood of the fish, a person needs to work here for at least two years. By the mood of the fish, you can understand whether it gets too much or too little feed. “You can tell if it is in a good range or has dropped for some reason just by its mood and behavior, without even measuring the oxygen,” the chief fish farmer said.

On average, over the course of a year, fish grow to about one kilogram, sometimes more. This depends on stocking density and other factors.

What is the most nutritious part of a fish?

Later, live fish are brought to the processing workshop. There are only three people working here, but they can process several hundred kilograms of fish a day and, if necessary, even several tonnes. The key to this process is practice: without it, no life hacks will help. The most challenging task is filleting, which involves removing every single bone from the raw fish.

“Before being sent for filleting, the fish are gutted and chilled. Depending on the size of the order, the fish may be smoked, chilled, made into chilled fillets in MAP packaging, or salted fillets. To make smoked fish, it first needs to be salted, then smoked at 26-28°C and dried. The smoking process takes about a day and results in a very beautiful and delicious fish,” the head of the processing workshop Natalya Sivakova said.

Salted and smoked fish is shipped all over the country. The farm works strictly on order, so there is no such thing as unsold inventory.

“We salt our fish in strict accordance with GOST quality standards. We use only salt and a small amount of preservatives, as lightly salted fish won’t keep without them. We don’t use chemical additives,” the head of the workshop assured.

Cold-smoked fish can be stored for up to 30 days. Different parts of the fish are cooked: whatever one likes best.

“They make back cuts, whole sides, headless cuts. They remove the backbone from the back to produce a side fillet. These are our main types of cuts. We also get the tesha from the back, which is in high demand,” Natalya Sivakova noted.

It turns out that tesha is the most tender and nutritious part of the fish, it is juicy and soft. That is why it is so popular.

“When we cut the fish into fillets and steaks, we are left with scraps: bellies, various trimmings, and spines. All of this goes into fish soup kits. These are also in demand. They are cheap and they all sell,” said workers at the site.

What will happen to trout production in Belarus?

Belarusian fish is in high demand, this is why the company has decided to expand production. This project is now in the final stage.

“We have built two additional fish production complexes, each with the output capacity of 1,000 tonnes per year. The output will increase by several times. And we are also building a complex in the town of Cherikov to produce caviar. The entire fish production cycle will be in in the same set of hands,” Yuri Kuksenkov, Director of Lokhva, shared immediate plans.

The new complexes will be commissioned by the end of the year, and Belarusian trout production volumes will increase substantially. And although Belarus has no sea, rainbow trout is no longer a delicacy. It is an affordable and very healthy product.

print version

print version make home page

make home page add to bookmarks

add to bookmarks